1

INITIAL PROJECT REQUIREMENTS

2

INNOVATIVE SOLUTIONS APPROACH

3

EXPERIMENTAL DEVELOPMENT

4

RESULTS

1. INITIAL PROJECT REQUIREMENTS

Our client, a large company in the energy sector that manufactures its own wind turbines and assembles its own wind farms, asked us for a product with characteristics that they could not find on the market and that no other company was willing to develop for them.

The problem that the client transmitted to us is that they were going to set up a new wind farm in an area with significant seismic activity, with the risks that this entails when it comes to installing any structure. The shaft (or tower) of the wind turbines to be installed is made of concrete and is divided into several sections that are joined together by means of a crown of steel sheaths in the lower section and another of large diameter corrugated bars in the upper crown (Male – Female). This assembly, being carried out in a region with seismic activity, forces them to hold the assembly by means of cranes until the joint between sections is strong enough to be safe in the event of an earthquake, which with a standard adhesive on the market can take up to 12 hours, a time that would make the project enormously expensive due to the cost of the cranes.

The product we are asked to develop must have good adhesion to both steel and concrete, which are the materials that will be used in the assembly of these structures. It must be a durable adhesive, with high resistance to ageing in service conditions, very fast curing and with good mechanical and thermal resistance properties. The developed product must resist mechanical stress in seismic conditions within a short time after application, namely less than 2 hours. This will allow the customer to save costs during the installation of the wind farm, as it will reduce the time of use of the cranes.

2. INNOVATIVE SOLUTIONS APPROACH

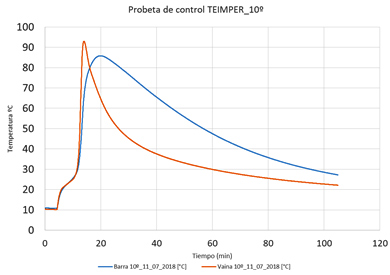

To solve the problem, GAIRESA proposed the design of an innovative epoxy formulation that could be applied by casting at high speed and whose high reactivity would allow rapid curing. The high reaction enthalpy of such an epoxy system is capable of causing a significant intrinsic temperature increase during the first few minutes of curing, which increases the chemical conversion of the reaction in a short time. The result would be an epoxy system capable of reaching its maximum mechanical and thermal properties in a short period of time.

3. EXPERIMENTAL DEVELOPMENT

The development of the proposed solution begins with the chemical study of the components that are going to form part of the epoxy formulation, choosing the most suitable and compatible ones to achieve the technical requirements originally proposed. After an initial battery of formulas, those that offer the most promising results are analysed in depth. For this purpose, GAIRESA’s laboratory uses numerous analysis techniques, including, among those used for this project, differential scanning calorimetry (DSC) for the study of reactivity and thermal resistance, and FTIR infrared spectroscopy for the study of reaction kinetics and the determination of the degree of chemical conversion.

Once these parameters were adjusted, simulation tests of the real anchorage were carried out at laboratory scale, in which the curing reaction was monitored to determine the exothermic peak and the chemical conversion of each tested formulation.

With the collaboration of the CITEEC Construction Laboratory, associated with the Faculty of Civil Engineering of the University of ACoruña, real anchors were manufactured in large concrete specimens, which were tested in order to verify that the anchor with GAIRESA’s formulation was able to withstand compressive stresses of 70 MPa and tensile adhesion of over 5 MPa, after a period of 90-120 minutes from pouring into the sheath.

4. RESULTS

Following the success of the test campaign on large concrete specimens, it was verified that the formulation developed by GAIRESA meets the initial requirements, managing to reduce even further the time required for setting in service at first, from 120 minutes to 90 minutes.

At the same time, an application procedure was developed in which all the parameters, times and operations to be carried out to handle the new product and meet the objectives of the project were established, conveying to the client the capacity to execute it on site.

This project resulted in 3 different formulations, each with its own characteristics and all certified for application in anchors and other structural adhesives:

BEPOX 2226-20C and BEPOX 2226-10C:

ultra-fast epoxy formulations, even at very low temperatures. Fast set-up time (less than 2 hours). Chemical anchoring resistant to seismic conditions.

BEPOX 2222

medium viscosity, medium reactivity epoxy formulation, ideal for concrete-to-concrete (old and new) and concrete-to-steel bonding.

The 3 formulations have been certified by an independent body with the CE Marking for Structural Adhesives, according to the UNE-EN 15274 standard.