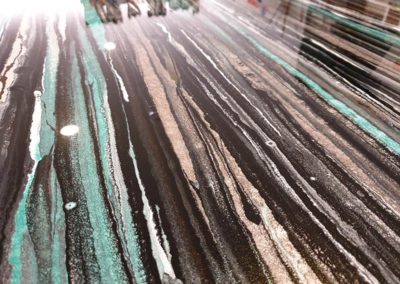

3D Floors – Epoxy Crystal

3D epoxy floors are a trend in decoration and architecture. This consists of installing images or photographs on a floor and coating them with a transparent epoxy resin for 3D floors as a protective layer, which gives the appearance of glass.. A variant of this trend is to apply a paint with a specific colour or design, which is then coated with the same highly transparent epoxy resin. This type of glass-clear epoxy resin is informally called by many other names that are incorrect from a technical and chemical point of view, such as liquid porcelain, although at GAIRESA we prefer to call them transparent epoxy or Crystal Epoxy.

3D flooring: application

Formulating a transparent epoxy resin emulating glass is relatively easy, but first impressions are not everything in this world. What GAIRESA has achieved is to improve the existing products on the market thanks to the know-how and experience accumulated over 40 years in the chemistry of epoxy resins.

We know that traditional epoxy resins have a natural tendency to yellowing, which can occur within a few weeks of installation. This means that, even if they are initially perfectly transparent, after a while they will take on a yellowish shade that will spoil their appearance. And this is difficult to fix afterwards. Action must be taken at the origin, which is the formulation of the transparent resin itself. There are two ways to avoid or at least delay this phenomenon by modifying the composition of the epoxy resin for 3D flooring:

- Add the appropriate amount of a protective additive that absorbs UV radiation in the 400 nm region.

- Replace the standard epoxy resin with a 100% aliphatic epoxy resin, which is intrinsically much more resistant to yellowing caused by solar radiation.

Epoxy resin for 3D flooring: GAIPOX® 2158 UV

At GAIRESA we have decided to combine both ways in our formulations, to ensure the maximum possible resistance to yellowing in a system of an epoxy-amine nature. Our GAIPOX® 2158 UV epoxy resin is designed taking into account the chemical principles explained above and its resistance to yellowing has been tested in an accelerated ageing chamber, demonstrating much greater stability and durability than standard epoxy systems, even if they include UV absorbers.

Another fundamental aspect to consider in these epoxy systems is the hardness and abrasion resistance of the product once installed and cured, as premature wear due to typical friction on a floor where people walk or drag furniture will ruin in a few days the good appearance initially achieved. Our transparent epoxy resins for 3D flooring, such as GAIPOX® 2158 UV, have Taber abrasion resistance values that are among the best on the market.

Aliphatic polyurethane resin for 3D flooring: GAIDUR® NANOCLEAR 80

If there is one product that is the king of 3D flooring, it is GAIDUR NANOCLEAR 80, a resin based on the chemistry that best resists solar radiation without the addition of any UV protection. The hardness and scratch resistance of this transparent resin makes it the best possible finish for a floor with these characteristics.